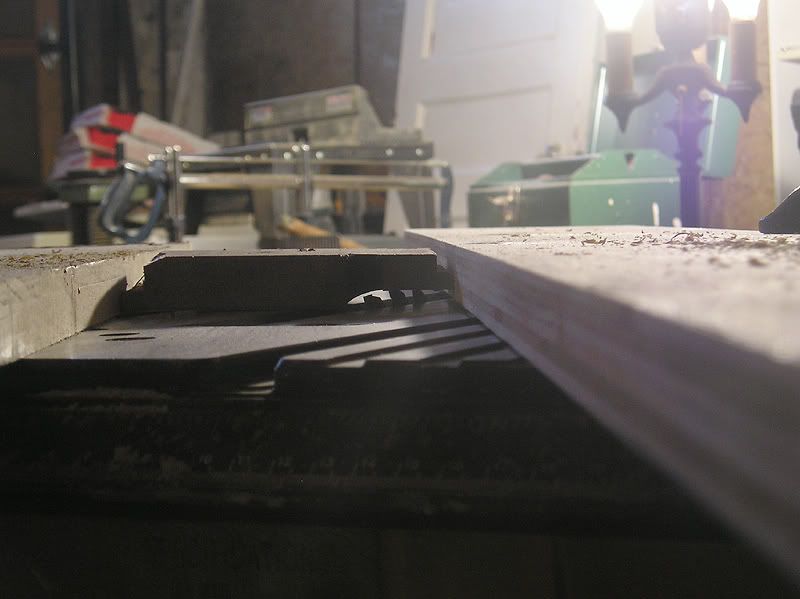

The issue is that the OSB was hastily installed to cover up the wall. "Why?", I hear you asking? Well, because part of the wall has some extreme water damage. So much so, that a few of the vertical studs are completely rotted, and many of the exterior tongue and groove boards are rotted, cupped, and warped. In the centre of the "bad" section, I can actually grab the stud, and if I shake it, the whole wall moves. SCARY!

They made an attempt at a repair, but it's laughable, and ineffective.

At this point, I'm thinking of simply building an entire secondary wall on the inside. This new wall would properly support the roof, and the weight would be on the concrete. I'm fairly sure they made the garage over a proper footing/etc, since the bottom under the wall seems to be cement. It's hard to tell, actually.

Here are some photos. They actually make it look less bad than if you were looking at it in person. :S

This first part just made me laugh, and scratch my head. I have NO idea why they didn't just remove the block, or shorten the piece of pine tacked to the stud.

And what's that block? It's actually an original plinth block (for a doorway) that's in reusable shape. And it was barely held on the wall by one nail.

Note that they had actually cut the OSB to go around this block, and it looked ridiculous: Click to see a "before" shot from a while back.

Then this is where things started to go downhill. I was wondering why they had added some 2x6s at the top of the wall. I removed a short length of it, and you can see that one of the two top studs is water damaged into an 'S' shape. You can also start to see some of the cupped t-g boards.

I did not remove the rest of the 2x6, since it might actually be holding something together, but this is how much more of it there is. It covers about 1/2 the length of the garage.

Here's the really bad spot. It continues up about another 2 feet (over the wood rack which is blocking the view). That centre stud is completely rotted into crumbly bits, and the other two are also damaged.

This spot is closer to the front of the garage (towards the street), and it's not quite as bad here, but it's not good either.

This shot shows the bad portion of the wall (towards the street). The corner stud is in line with the centre of the ladder (for reference). From the corner, I have maybe 1-2 feet that are ok, then it's bad up to the edge of the photo.

The good news is that the other half is in great shape. This is the half that's towards the neighbour's house (the building next door is literally that concrete block wall.

So ummm, yeah. Fun times, eh? I think this is the point where most people would break down and cry their eyes out, but I'm actually not that surprised/upset. I can fix it, it's just gonna be a lot of extra work to do. :(